Find out more about the quality and responsibility involved at every stage of the supply chain process that makes us stand out from the rest.

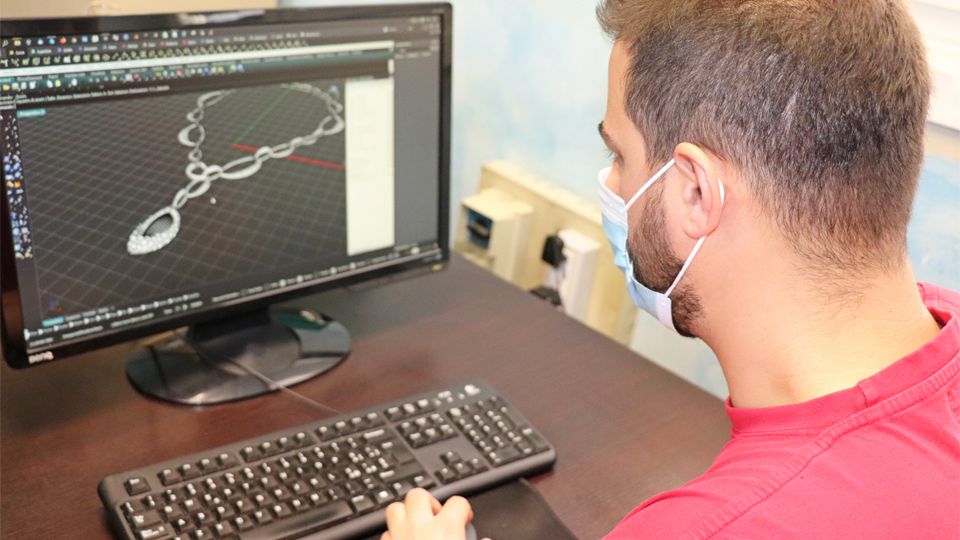

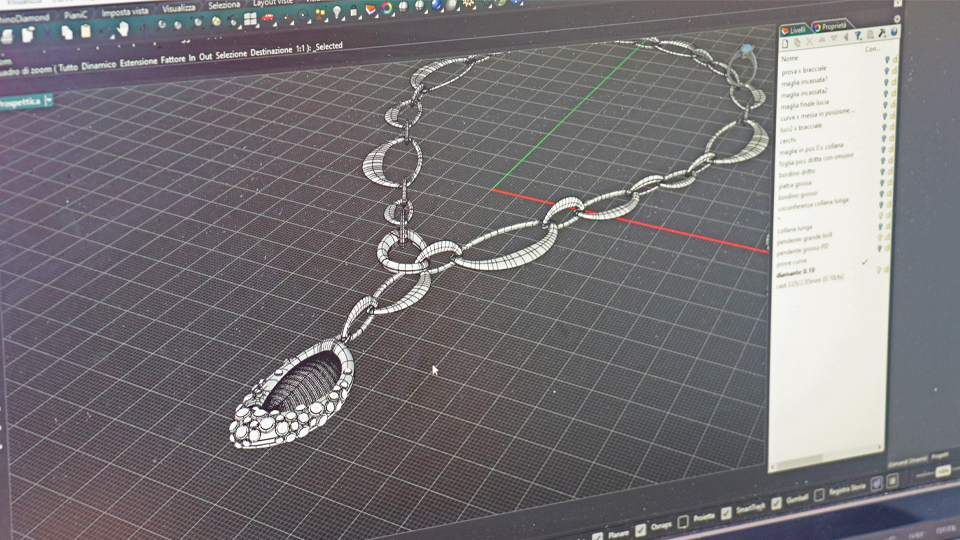

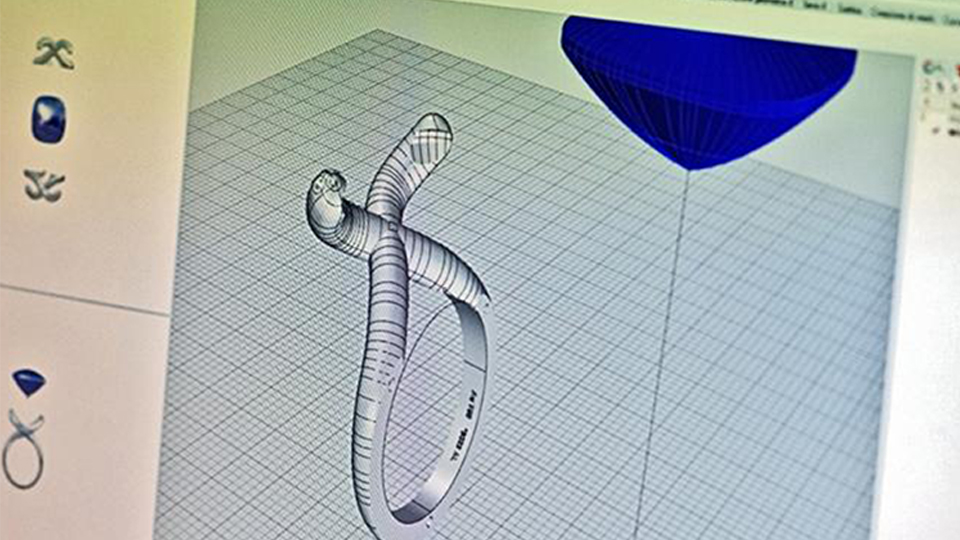

Since 1994, CAD design has made it possible to make jewellery more quickly and rigorously as compared with traditional techniques.

With 3D printing having already been introduced in the early years of the new century, the design phase is increasingly more precise and reliable.

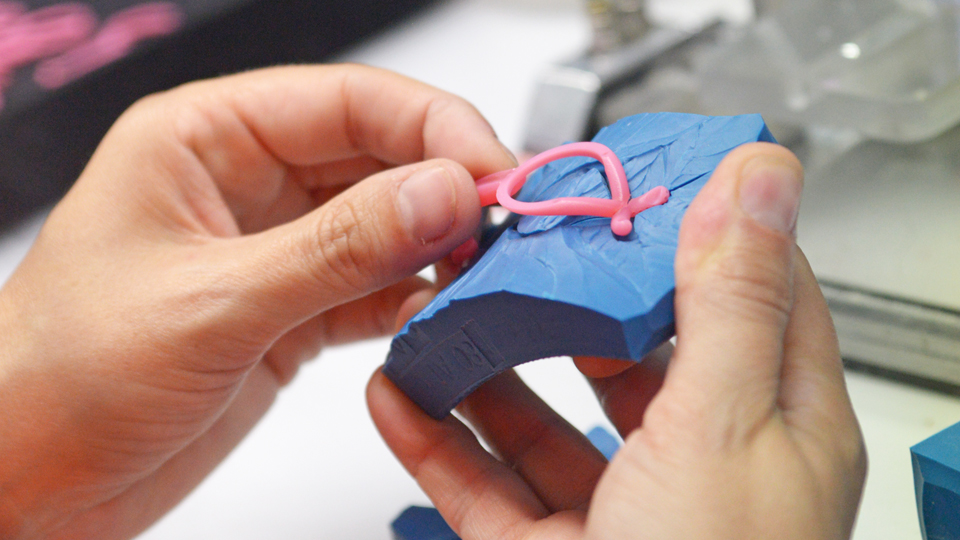

New technologies and digital creation systems have not made us forget our origins. This is why we also produce items of jewellery following traditional methods.

Lost wax casting is a very ancient method for the production of various objects, yet it’s still used today in the world of jewellery making. The procedure consists in making a model that is reproduced with a softer material such as wax, to then create a plaster mould around it.

We have been carrying on a passion that has been handed down from generation to generation. Created by the expert hands of our artisans, just like in the past, Stilnovo jewellery testifies to the values of the highest goldsmith tradition.

Setting precious stones on noble metal is an ancient art, which today uses cutting-edge tools and technologies to enhance the beauty, light and soul of a gem.

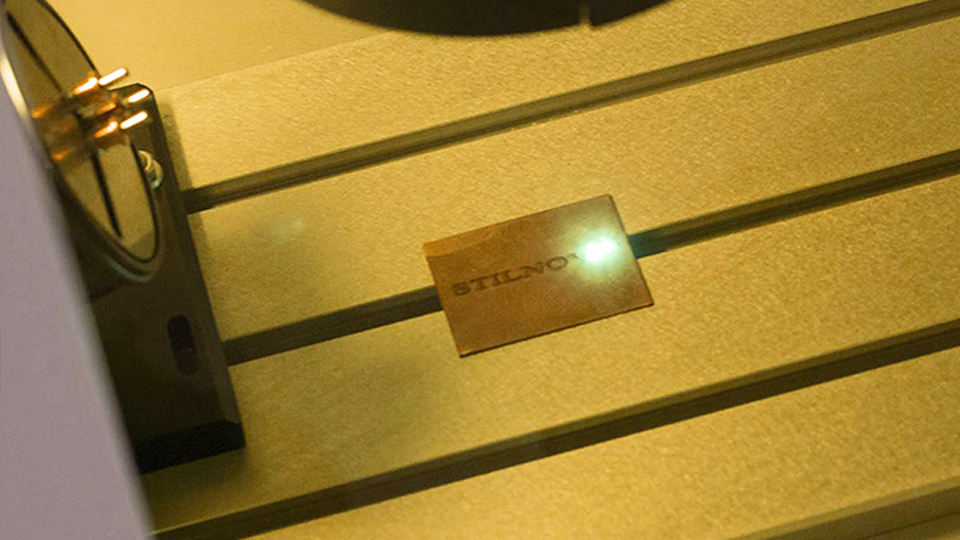

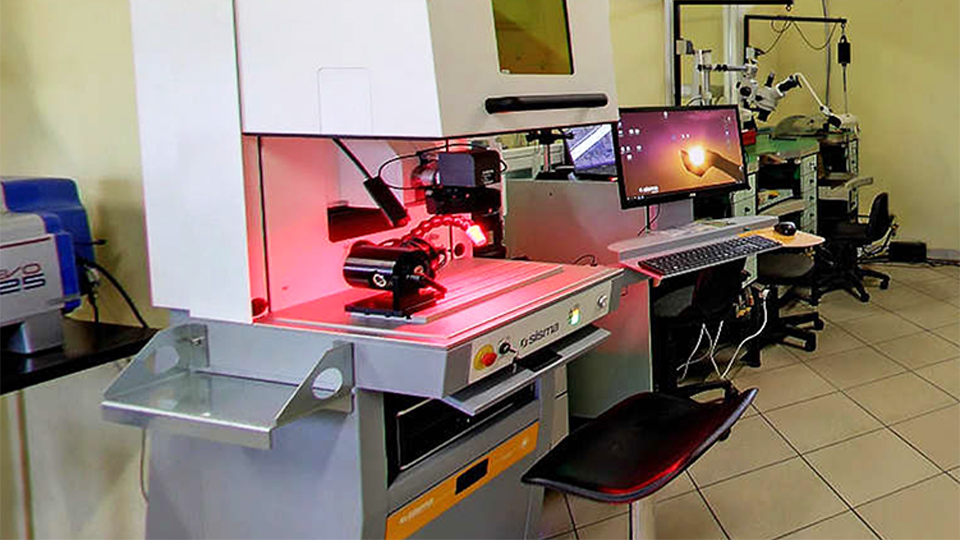

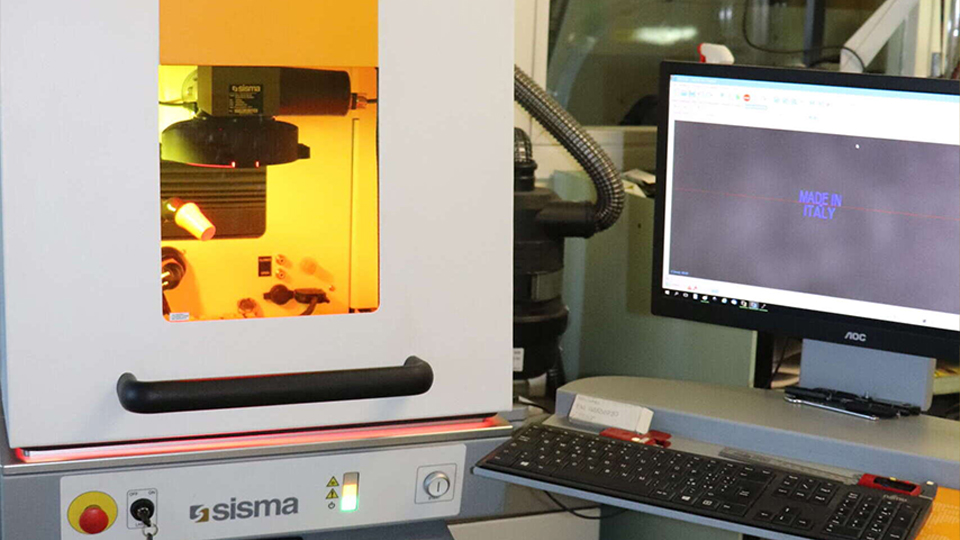

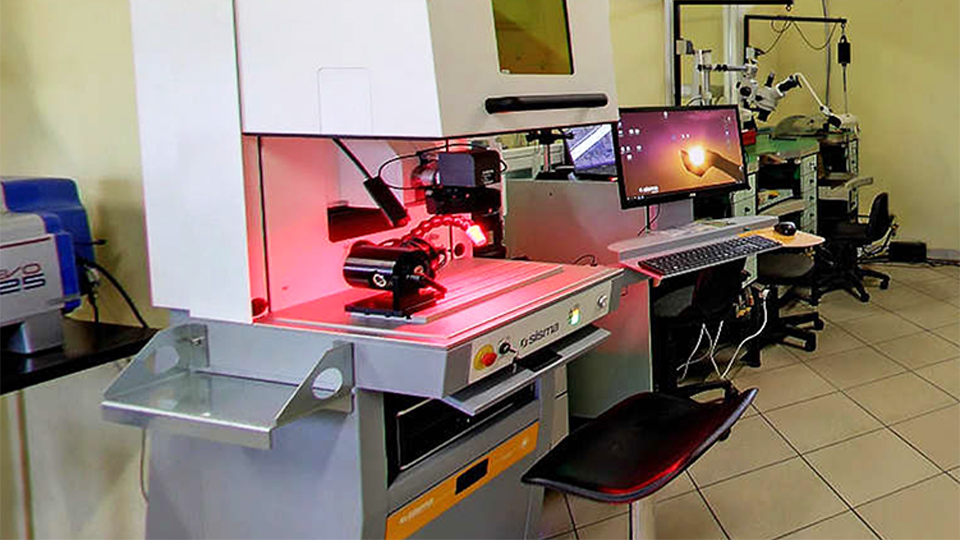

Each item of jewellery can be engraved, personalized, numbered and made unique. The latest generation technology also makes it possible to avoid counterfeits being made.

Jewellery polishing is essential to make both new and old items of jewellery shine without changing shapes and gems. Thanks to cutting-edge machinery, we are able to satisfy even the most demanding of eyes.

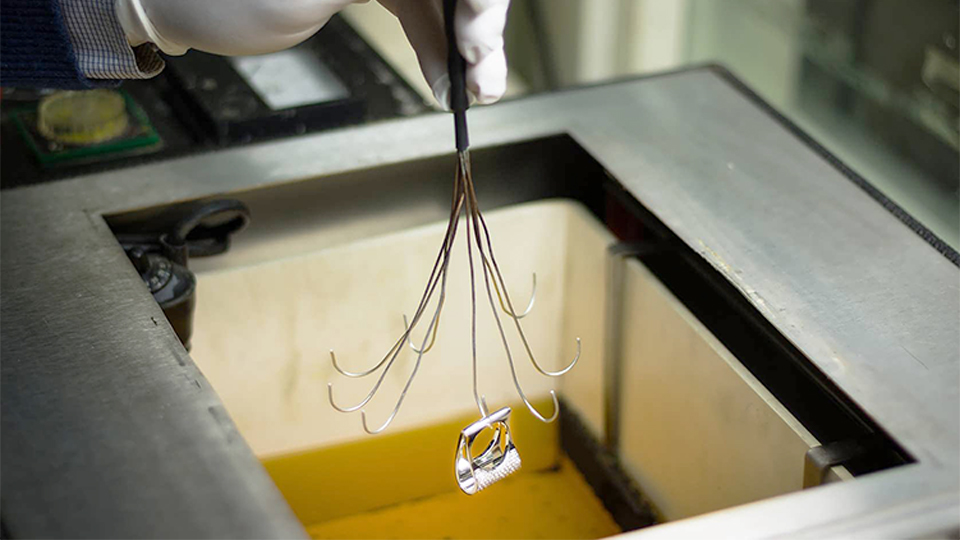

Rhodium plating is the most widely used surface treatment. It consists in covering, by means a galvanic deposition process, white gold jewellery with a layer of rhodium, the whitest metal in the periodic table. The process is carried out internally; it is controlled and guarantees long-lasting results.

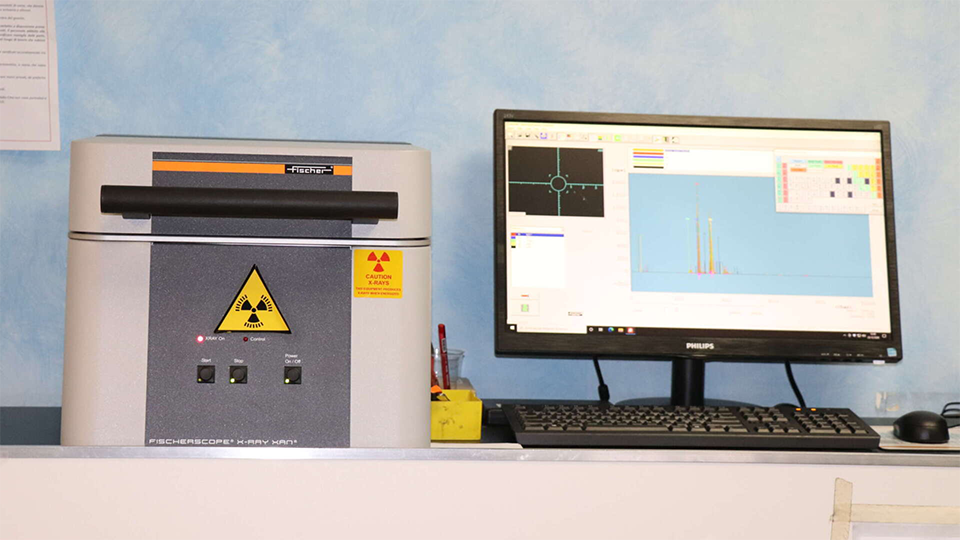

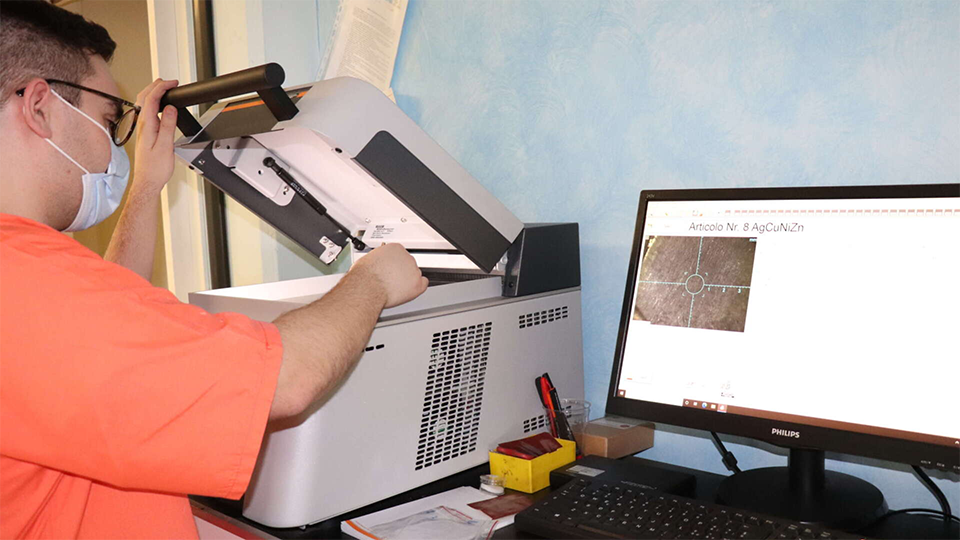

We at Stilnovo care about our jewellery. Before being put onto the market, they must pass strict testing procedures, as well as meet precise quality parameters.

The real engine of our production is our high-level workmanship: our goldsmiths are in no doubt as to what it takes to marry their dextrous know-how with technology, in order to ensure that excellent results are achieved.

An XRF machine is used to analyse the fineness of metals, which is performed immediately after the melting process and guarantees that the precious metal alloy complies with all legal requirements.

Stilnovo owns 7 industrial design patents, of which 2, over twenty years old, have become common heritage of mankind. The search for innovative solutions, of which patents are an expression, is the common thread that ties together the diverse souls of our know-how.

Via Cappelletta, 6, 15046 San Salvatore Monferrato AL

Stilnovo Srl © 2023. All rights reserved.

Crafted by SMARTEGO